Experience our world-leading fire resistance testing facility – built to meet the industry's future fire safety needs

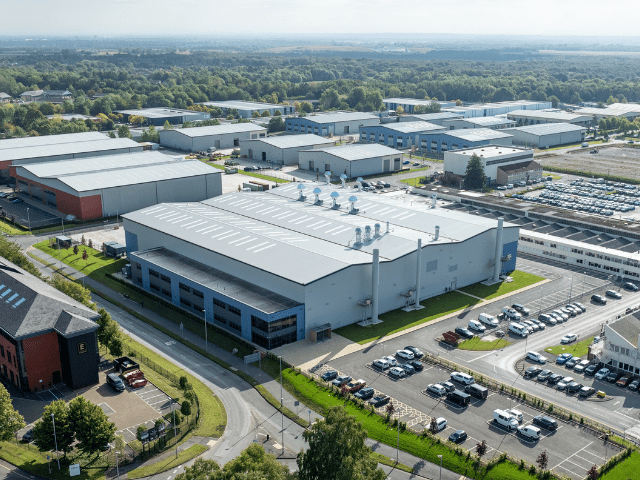

Our new Warringtonfire laboratory opens in Birchwood Park, Warrington, UK, in January 2025. With expanded capacity and advanced technologies, it will be one of the largest and most state-of-the-art fire testing facilities in the world, providing fire resistance testing, technical and certification services to customers globally. Located in Birchwood in North West England, the site is easily accessible from surrounding cities, with close motorway links to the M6 and the M62.

On this page, you can learn more about this facility, access information about our progress, and explore our latest blogs and videos. Contact us now to book your fire resistance testing for 2025 and beyond in our new world-leading facility in Birchwood Park.

Frequently Asked Questions

To ensure a smooth transition, we’ve prepared a comprehensive FAQ guide detailing practicalities and the site's new processes, grouped into the following sections:

- General Information

- Deliveries

- Operations and Transition

- Safety and Security

- On-site Work and Fabrication

- Your Account: Billing and Payments.

View the latest developments at our Birchwood Park facility

The construction phase of Warringtonfire’s flagship fire resistance testing facility is now complete, with the preparations for the state-of-the-art laboratory now on the final stretch before it officially opens in January 2025.

The new laboratory will offer fire resistance testing for doors, glass and glazing, fire stopping, suspended ceilings, floors, structural steelwork protection, smoke curtains and components, walls and partitions, and much more.

What do you need to know?

The facility addresses the growing customer demand for Warringtonfire’s product testing, which is driven by:

- increasing regulatory requirements

- the rising importance of third-party certification

- greater emphasis on product assurance

- the need for shorter testing lead times.

Our new facility is designed to meet this increased demand. It represents an almost 80% increase in size over our existing facility in the region and triples Warringtonfire’s testing capacity in the medium term.

Our new facility unites the latest technology, increased capacity and technical expertise to create a world-leading fire resistance testing service:

- World-class fire testing facility with state-of-the-art equipment, providing testing, technical and certification services for all your critical fire safety products and systems.

- Unparalleled expertise provided by a 200-strong team of fire safety experts, ready to fulfil your end-to-end needs. We are one of the world’s largest teams of fire technical experts.

- Comprehensive testing capabilities performed to British, European and International standards, supporting CE marking, UKCA and UKNI marking, and third-party certification.

- Enhanced customer experience offering considerable preparation and test viewing areas, and generous welfare amenities.

- Extensive global reach serving manufacturers, specifiers, and contractors from the UK, Europe, and worldwide with independent fire testing and certification.

- Sustainability and safety are top of our agenda. Our facility utilises extensive measures to maintain air quality, reduce energy use and minimise environmental impacts.

- Client privacy is our priority with our meticulously designed work flows and provisions to ensure confidentiality throughout the fire testing process.

Our Services and Capabilities

- Doorset and hardware testing

- Structural steelwork protection testing

- Fire stopping product testing

- Floor and suspended ceiling testing

- Glass and glazing systems testing

- Smoke curtains and component testing

- Wall and partition systems testing

- Fire product and personnel certification

- Non-fire product and personnel certification

- Marine certification.

Enhanced Customer Experience

Advanced testing equipment

Our laboratory is equipped with the latest fire testing technology, allowing for more accurate, faster testing results across a wider range of materials and products. This includes enhanced capabilities for testing complex fire scenarios.

Increased capacity

Our facility is designed to meet the growing needs of industries with rigorous fire safety demands. By expanding our preparation and frame storage areas in size and number, and optimising workflow efficiency, we can now handle a larger volume of tests, resulting in greatly reduced lead times and more agile service delivery.

Meticulously designed to prioritise client privacy

Dedicated client viewing areas, shielded test preparation areas, and confidentiality protocols protect your intellectual property and safeguard sensitive information.

Partnership-driven approach

Our facility is designed with client collaboration in mind. Clients can observe tests, consult with Warringtonfire’s experts, and receive immediate feedback on performance. This collaborative client-centric approach ensures that testing aligns closely with project goals and requirements. We offer customised testing solutions, whether it’s bespoke testing methods, tailored reporting, or specific compliance certifications.

R&D and innovation support

We offer support in the development of new fire-resistant materials, products, and technologies. This enables you to innovate while ensuring fire safety compliance from the early stages of product development.

Operations consolidated under one unit

Our full-service facility simplifies the process, offering fire resistance testing, technical and certification services under one roof.

Improved welfare amenities

Clients benefit from accessible showers, locker rooms and toilets; meeting and conference rooms, viewing areas and social spaces such as canteen areas; plentiful parking with 175 bays, including 10 disabled and 10 EV charging spots; as well as the Birchwood Park central site facilities.

Sustainability

The new facility utilises extensive measures to maintain air quality, reduce energy use and minimise environmental impacts. These measures include:

- Built-in recycling systems

- Smoke and odour capture and treatment

- Dedicated cold abatement system to eliminate smoke generated externally from the furnace

- Energy-efficient fans

- Upgraded power supply transformers that consume minimal electricity when idle

- Electric vehicle infrastructure, including a fleet of EV forklifts and charging points

- Optimal insulation with commendable U-values

- Meticulous attention to air tightness

- Well lit, through a combination of natural light from skylights and LED lighting that delivers a high lux level

- Set up to accept a blend of clean hydrogen and natural gas once local infrastructure offers this service.

Equipment & Technologies

The new custom-built facility will add unique capabilities, eventually comprising eight state-of-the-art fire resistance testing furnaces and a multitude of advanced technologies:

- Three horizontal furnaces designed to evaluate the fire performance of products or assemblies built horizontally

- Three vertical furnaces designed to evaluate the fire performance of products or assemblies built vertically

- One indicative furnace capable of testing both vertically and horizontally on a smaller scale, with a potential second

- Eighteen wall preparation bays and additional preparation areas with space for curing and frame storage

- Seven confidential temperature-controlled spray booths with the potential for a further two

- Purpose-built autofed shot blast booth with abrasive recovery system and modern blast machine for improved efficiency.

Why Choose Warringtonfire

Our engaged experts are leading technical authorities in their fields, with many sitting on committees for government and industry associations, helping to shape the future of the industry.

As well as this, our certification schemes have been serving the industry for decades, with our installer scheme FIRAS recently celebrating its 30-year anniversary.

View the latest update